P/O Invoice system is the software that specializes in sales xontrl and purchase Control.

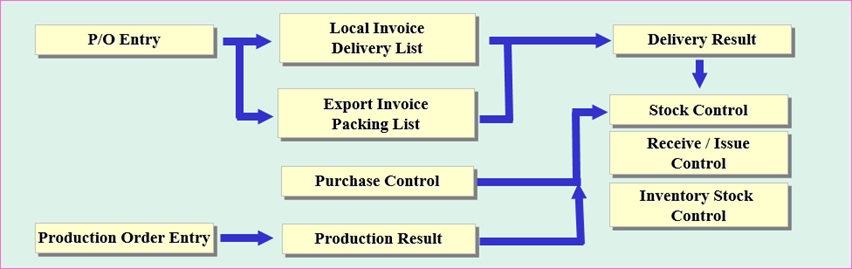

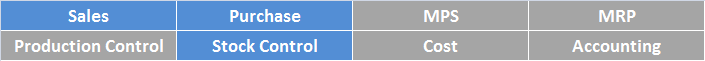

Processing of sales control, quotation → P/O input → Delivery Note → Delivery Result → Invoice input, in the purchase, subcontract management, P/O input → P/O report → P/O approve → Invoice input.

In the future, you can upgrade to the ERP, Production Control, Sales System and Barcode system.

Basic business flow is Quotation→customer's P/O input→Delivery Note→Delivery result→Invoice input. Customer P/O and Invoice are needed to Approve.

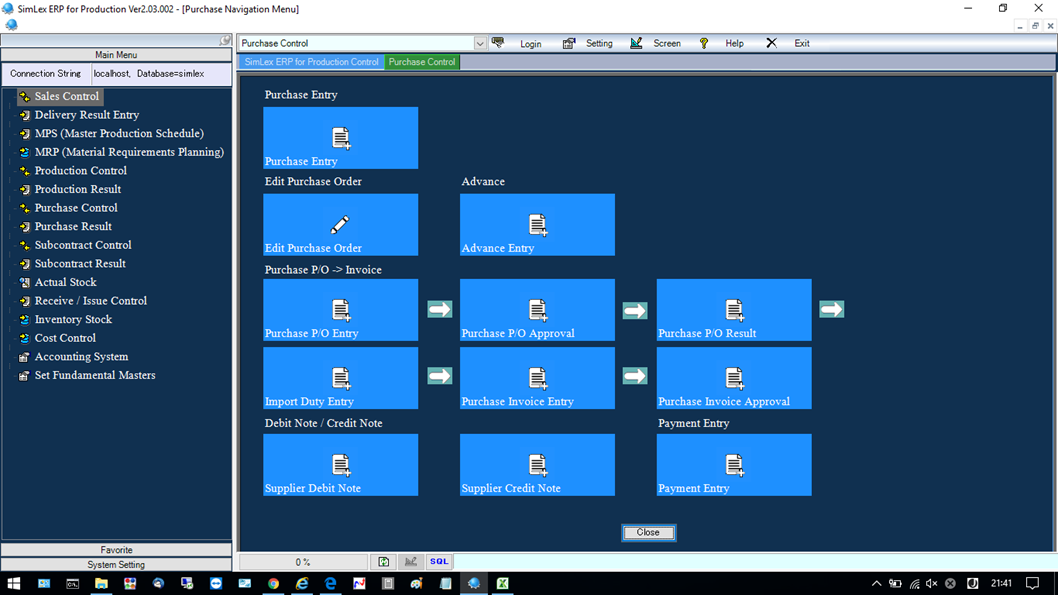

Basic business flow is P/O Entry / Report→P/O Approval→Receved Result Entry→Supplier Invoice Entry→Invoice Approval.

・Customer's P/O entry、Confirmation P/O and printing of Confirmation P/O report.

・Corresponding to the local invoice and export invoice.

・Standard of trade condition is CIF・FOB・C&F・DDP・DDU.

・Pallet management of export invoice packing list.

・Instructions of Local delivery report and Export packing List.

・Sales advance Entry, debit note/credit note Entry.

・Quotation Entry and Print out of quotation report.

・P/O、Invoice Approval.

・Actual sale for customer,Actual sale for end user,Actual sale for classification.

・Create special Item,BOM Pattern.

・Month Progress,Month Schedule,Weekly schedule,Delivery back order list.

・Introduction of editing the production order by manual order.

・Issuance of production Period order and support to serial number printing.

・Input and editing functions of the Defective.

・Actual production input can be use the barcode system and separate to production by order and production by number.

・Issuance of production order list, order slip and picking list printing.

・Display of the lot trace during production work in process.

・Editing Purchase /Subcontract Order by manual order.

・Issuance P/O and print the order to supplier.

・P/O Input can be done using a barcode system.

・Input Purchase Advance, Debit Note and Credit Note.

・Printing of order list,order slip and Picking List Printing.

・Import Duty input on overseas purchases.

・Display of the purchase lot trace.

・P/O and Invoice approval.

・Purchase order record can divide according to Supplier List, End user or Classification.

・Actual Stock by Location, the days of stock-in and stock-out and stock value.

・Actual stock by Item, stock value, quantity of purchase order(include Safety Stock).

・Display of BOM Explosion Actual stock.

・Standard receive、Input data of the products received.

・Standard Issue, Input data of the products issued.

・Stock movement processing, Input the material of moving between location.

・Stock transfer processing, Input the material transfer between locations or change Item name to another Item.

・Display of the stock movement record.

・Display of the stock transfer record.

・Display of receive and issue history.

・The creation of inventory in each location.

・Edit the inventory data created and creating monthly inventory to be actual stock.

・Display of monthly stock.

・Calendar Master, Country Master, Currency Master, Currency Rate Master, Tax group master.

・Payment master, Bank master, Supplier bank master, Company master, Customer master, Supplier master.

・Person master, Warehouse master, Area master, Location master, Receive / Issue master

・Process master, Equipment master, Quality of Defective master, BOI master

・Production Item master, Purchase Item master, Unit master, Classification master

・Structure master, Sales price master, Purchase price master, Category master